Ndodo ya pisitoni ya S45C Yolimba Ya Chrome Ya Pneumatic Cylinders

The pneumatic cylinder hydraulic piston rod imatchedwanso chrome-plated rod.Ndi ndodo yokhala ndi pamwamba yomwe imapangidwa ndi mphero yapadera komanso plating yolimba ya chrome.Amagwiritsidwa ntchito kwambiri mu masilindala osiyanasiyana, ma silinda a hydraulic, ma CD, matabwa, kupota, makina osindikizira ndi utoto, magawo oponyera ndi zida zina zodziwikiratu chifukwa cha kuuma kwake, zomwe zimatha kuwonjezera moyo wautumiki wa makina olondola wamba ndi zida.

Tidatengera kuzizira koyenera, kulemekeza ndi kupukuta kuti tipange pisitoni ya silinda ya hydraulic piston, cholinga chilichonse chaukadaulo chimakwaniritsa mulingo wadziko lonse.

Tsatanetsatane Tsatanetsatane

Zida: CK45(GB/T699-1999)

Kufotokozera kwamakina:

Kulimba kwamphamvu(Mpa):≥600N/mm2

0,2 Kupsyinjika kwa Zokolola (Mpa):≥355N/mm2

Elongation: min.16%

Makulidwe a Chrome: φ<20mm≥15μm,kuchokera φ20mm>20μm

Kukula: Ra- 0.2

Kulimba kwa Chrome Layer:850HV-1050HV

Kulekerera kwa Diameter: f7,f8

Kuwongoka: <0.1um/1000mm

Ovality: < 1/2 m'mimba mwake kulolerana

Kuyesa kwa Corroseston Test: ISO 10289:1999,IDT

M'mimba mwake: 3-120mm (GCr15) 3-40m(SUS440C)

Mkhalidwe woperekera: Wamba, Induction Harden, Q+T

Chemical zikuchokera tebulo

| KUPANGA KWA CHEMICAL(%) | |||||||

| Zakuthupi | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0.035 | 0.035 | ||

| Chithunzi cha ST52 | <= 0.22 | <= 1.6 | <= 0.55 | 0.035 | 0.035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.1-0.50 | 0.035 | 0.035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 | |||

| Diameter | Kulemera | Kulekerera | Kulekerera | Kulekerera |

| mm | Kg/m | f7 (μm) | f8(μm) | h6(μm) |

| 6 | 0.22 | -10--22 | -10--28 | 0--9 |

| 8 | 0.39 | -13--28 | -13--35 | 0--9 |

| 10 | 0.62 | -13--28 | -13--35 | 0--11 |

| 12 | 0.89 | -16--34 | -16-43 | 0--11 |

| 16 | 1.58 | -16--34 | -16-43 | 0--11 |

| 18 | 2.00 | -16--34 | -16-43 | 0--13 |

| 20 | 2.47 | -20-41 | -20-53 | 0--13 |

| 22 | 2.99 | -20-41 | -20-53 | 0--13 |

| 25 | 3.86 | -20-41 | -20-53 | 0--13 |

| 28 | 4.84 | -20-41 | -20-53 | 0--13 |

| 30 | 5.55 | -20-41 | -20-53 | 0--16 |

| 32 | 6.32 | -25-50 | -25-64 | 0--16 |

| 36 | 8.00 | -25-50 | -25-64 | 0--16 |

| 38 | 8.91 | -25-50 | -25-64 | 0--16 |

| 40 | 9.87 | -25-50 | -25-64 | 0--16 |

| 45 | 12.49 | -25-50 | -25-64 | 0--16 |

| 50 | 14.22 | -25-50 | -25-64 | 0--19 |

| 55 | 15.43 | -30-60 | -30-76 | 0--19 |

| 60 | 18.66 | -30-60 | -30-76 | 0--19 |

| 65 | 26.07 | -30-60 | -30-76 | 0--19 |

| 70 | 30.23 | -30-60 | -30-76 | 0--19 |

| 75 | 34.71 | -30-60 | -30-76 | 0--19 |

| 80 | 39.49 | -30-60 | -30-76 | 0--22 |

| 85 | 44.58 | -36-71 | -36-90 | 0--22 |

| 90 | 49.98 | -36-71 | -36-90 | 0--22 |

| 95 | 55.68 | -36-71 | -36-90 | 0--22 |

| 100 | 61.70 | -36-71 | -36-90 | 0--22 |

Kodi f7 ndi f8 tolerance standards ndi ziti:

Kulekerera kwa f8 ndikokulirapo kuposa f7, ndipo kuyikako kumadalira mulingo wofananira wa dzenje lololera.Mwachitsanzo, pamene kukula koyambira ndi 10-18, f8(-0.016,-0.034), f7(-0.016,-0.027), kupatuka kwa kulolerana kuwiri kumakhala kofanana, mtundu wa f7 ndi wocheperako, ndi chilolezo. osiyanasiyana unsembe zoyenera ndi ang'onoang'ono.

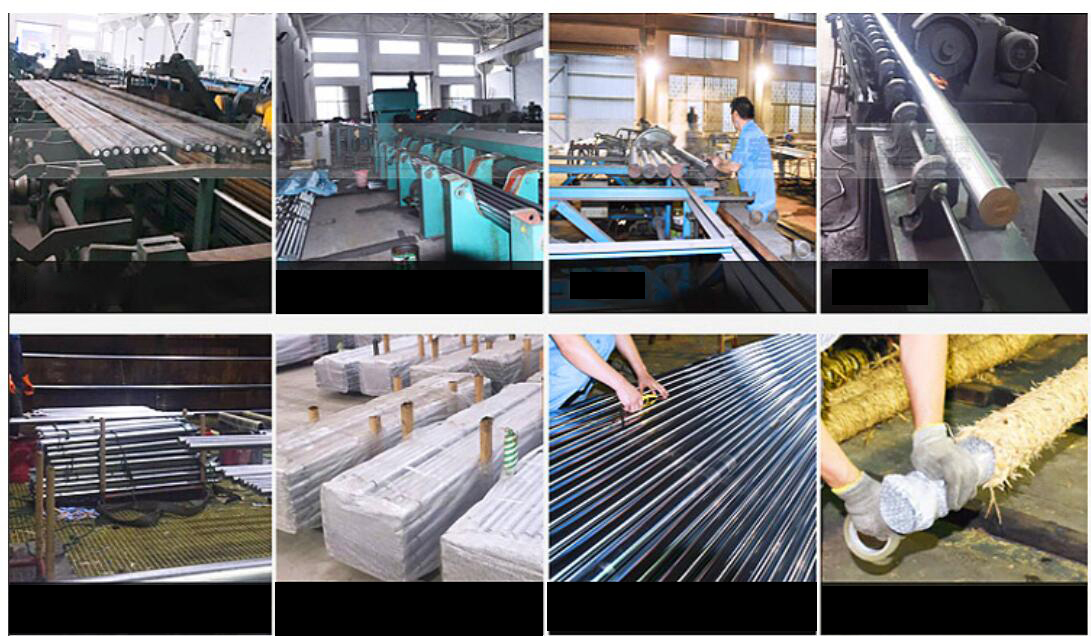

Mayendedwe Opanga

Khwerero 1: Peeling / Kuzizira Kokoka:

Kujambula kozizira ndi ukadaulo wowongolera wa pneumatic cylinder piston rod.Kwa pneumatic cylinder hard chrome plated ndodo, kujambula kozizira kumatanthauza kujambula pansi pa kutentha kwabwino kuti mukwaniritse mawonekedwe ena ndi zinthu zina zamakina.Poyerekeza ndi mawonekedwe otentha, zinthu zozizira zomwe zimakokedwa zimakhala ndi zabwino zake zolondola kwambiri komanso kumaliza bwino pamwamba.

2 Gawo: Kuwongoka

Gawo ili titha kuonetsetsa kuti ndodo yolimba ya chrome ndiyowongoka mokwanira.Ndikofunikira kwambiri, mukayiyika mkati mwa silinda ya pneumatic.Kuwongoka kokhazikika ndi 0.2mm/m.

3 Khwerero: Kulima

Honing processing ndi njira yabwino yopangira zinthu zomwe zimathandiza kuti pneumatic cylinder pisitoni ndodo ikwaniritse zolondola kwambiri, zapamwamba zapamwamba komanso moyo wautali.Ikhoza kupititsa patsogolo kulondola kwa mawonekedwe, kulondola kwa mawonekedwe ndi kuchepetsa mtengo wa Ra, koma sikungasinthe malo a dzenje ndi malo ena.

Khwerero 4: Kupukuta ndodo yachitsulo

Kupukuta kumatanthauza kugwiritsa ntchito makina, mankhwala kapena electrochemical zotsatira kuti achepetse kuuma kwapamwamba kwa ndodo ya pneumatic cylinder pisitoni kuti pakhale malo owala komanso osalala.Ndi kugwiritsa ntchito zida zopukutira ndi tinthu tating'onoting'ono tomwe timapukuta kapena zinthu zina zopukutira kuti zisinthe pamwamba pa ndodo ya silinda ya pneumatic.

Gawo 5: Kuyika kwa Chrome

Kuyika kwa Chrome kumatanthawuza kuyika chromium ngati zokutira pa ndodo yolimba ya chrome.

Chosanjikiza chopangidwa ndi chromium chimakhala ndi kuuma kwakukulu, ndipo kuuma kwake kumatha kusiyanasiyana mkati mwa 400-1200HV molingana ndi kapangidwe ka njira yopangira ndi kukonza.Chophimba cha chrome chimakhala ndi kutentha kwabwino.Mukatenthedwa pansi pa 500 ℃, palibe kusintha koonekeratu pakuwala komanso kuuma.Kutentha kumayamba kukhala oxidize ndikusintha mtundu kutentha kukakhala pamwamba pa 500 ℃, ndipo kuuma kumachepa kukakhala pamwamba pa 700 ℃.Kuthamanga kwachitsulo kwa chrome wosanjikiza ndi kakang'ono, makamaka kokwanira kowuma kowuma, komwe kumakhala kotsika kwambiri pakati pa zitsulo zonse.Chifukwa chake, wosanjikiza wa chrome ali ndi kukana kwabwino kovala.

Chosanjikiza cha chromium chimakhala ndi kukhazikika kwamankhwala.Zilibe mphamvu mu alkali, sulfide, nitric acid ndi ma organic acid ambiri, koma zimatha kusungunuka mu pneumatic acid (monga pneumatic acid) ndi sulfuric acid yotentha.Pakuwunika kowoneka bwino, chiwonetsero cha chromium chimakhala pafupifupi 65%, chomwe chili pakati pa siliva (88%) ndi faifi tambala (55%).Chifukwa chromium sisintha mtundu, imatha kukhalabe ndi mawonekedwe ake kwa nthawi yayitali ndipo ndi yabwino kuposa siliva ndi faifi tambala.

Khwerero 6: Ndodo yopukutidwa ndi Chrome Kupukutira pambuyo poyala

Electroplating ndi kupukuta: ndi njira ziwiri zosiyana zochizira zitsulo ndi zinthu zina.Yoyamba ndi mankhwala mankhwala, ndipo chomaliza ndi makina mankhwala.

Electroplating: Njira yogwiritsira ntchito electrolysis kulumikiza filimu yachitsulo pamwamba pa chitsulo kapena zinthu zina.Itha kuletsa dzimbiri, kupititsa patsogolo kukana, mphamvu zamagetsi, kuwunikira komanso kukulitsa kukongola.

Kupukuta: Gwiritsani ntchito zida zosinthira zopukutira ndi tinthu tambiri tonyezimira kapena zinthu zina zopukutira kuti musinthe mawonekedwe a workpiece.Kupukuta sikungawongolere kulondola kwa mawonekedwe kapena kulondola kwa geometric kwa chogwiriracho, koma cholinga chake ndi kupeza malo osalala kapena gloss.

Khwerero 7: Kuyesa Kwabwino kwa Chrome

Ndodo za pisitoni zomwe zakhala zikuyenda ndi electroplating ndi kupukuta njira nthawi zambiri zimatsagana ndi zolakwika zokutira monga maenje a chrome ndi pitting.Kukula ndi kuchuluka kwa zolakwika izi zimakhudza mwachindunji magwiridwe antchito a pisitoni.Kuchepetsa zotsatira za zolakwika izi pa ndodo ya pisitoni, mbali imodzi, pokonza zinthu zopangira, kukonza ukadaulo wokonza, komanso kuchepetsa kupezeka kwa zolakwika;Komano, m'pofunika kuti azindikire molondola plating zolakwika pambuyo ndondomeko kupukuta kupewa mankhwala osayenera kuchoka fakitale.Mainjiniya a Autoair amazindikira kuti ali ndi vuto lodziwikiratu mothandizidwa ndi chidziwitso cha sayansi yazithunzi

8 Gawo: Kulongedza katundu

FAQ:

Q1: Kodi ndodo ya pneumatic silinda pisitoni ndi chiyani?

A: Ndodo ya pisitoni ndi gawo lofunikira komanso lofunikira pa silinda iliyonse ya hydraulic kapena pneumatic.Ndodo ya pisitoni nthawi zambiri imakhala yayitali yopangidwa ndi chitsulo cholimba cha chrome chokhazikika chomwe chimatumiza mphamvu yopangidwa ndi pisitoni kupita kumakina omwe akugwira ntchitoyo.

Q2: Kodi mfundo ya pneumatic silinda piston ndodo ndi chiyani?

A: The pneumatic yamphamvu pisitoni mu yamphamvu amanyamula kukankhira kapena kukoka mphamvu kwaiye ndi mpweya, ndipo mwachindunji amachita pa pneumatic yamphamvu pisitoni ndodo yolumikizidwa ndi pisitoni, ndiyeno pneumatic yamphamvu pisitoni ndodo chikugwirizana ndi katundu workpiece kusuntha. kumangosinthasintha.

Q3: Kodi zopangira zanu za pneumatic cylinder piston ndodo ndi ziti

A: Kawirikawiri, pneumatic yamphamvu pisitoni ndodo ya yamphamvu pneumatic kusankha 45 # zitsulo monga zopangira.Ngati silinda yopangidwa iyenera kugwiritsidwa ntchito pamalo apadera, 304 zitsulo zosapanga dzimbiri zitha kugwiritsidwanso ntchito

Q4: Bwanji kusankha 45 # zitsulo monga zopangira

A: 45 # chitsulo ndi apamwamba mpweya structural zitsulo ndi otsika kuuma ndi kudula mosavuta.Pambuyo kuzimitsa, kuuma kwake pamwamba kumatha kufika 45-52HRC.Ndipo imathanso kukhala ndi ntchito yabwino yodulira komanso kulimba mtima, kulimba ndi zina zambiri zamakina, chifukwa chake ndi chimodzi mwazinthu zomwe zimagwiritsidwa ntchito kwambiri pamagawo a shaft.

Q5:Kodi makina opangira ma pneumatic cylinder piston ndodo ndi chiyani?

A: Kuti mupeze makina okhazikika, kuwongola pamanja kwa ndodo ya pisitoni sikuloledwa makinawo akayamba.Choncho, ndondomeko yowongoka iyenera kuchitidwa musanayambe kukonza.Chifukwa cha kusasunthika kosasunthika kwa chogwirira ntchito, kutembenuka kwaukali ndi kutembenuka kwabwino kuyenera kuchitika panthawi yopanga makina kuti makinawo akhale olondola.Njira yogwirira ntchito ya pisitoni ndodo ikubwerezanso kuyenda kwa mzere.Kuti apititse patsogolo moyo wautumiki wa ndodo ya pisitoni, pamwamba pake payenera kukhala ndi chrome-yokutidwa kuti ipititse patsogolo kuuma kwake komanso kukana kuvala.Pambuyo pa plating ya chrome, chithandizo chopukutira chimafunika kuti chikhale chovuta kwambiri, kuchepetsa mikangano, ndikuwongolera kusindikiza.Popeza njira yopukutira imakhala yopanda mphamvu pamtundu wakunja wa ndodo ya pisitoni, chogwiriracho chiyenera kukwaniritsa kuuma kwapamwamba pamaso pa chrome plating.Choncho, m'pofunika kuwonjezera njira yabwino akupera pamaso pa chrome plating ndondomeko (mwatsatanetsatane akupera kungathandizenso pamwamba adhesion wa chromium. ).Kutengera kuwunika komwe kuli pamwambapa, njira zowongolera bwino za ndodo ya pisitoni ndi: kuwongola-kupotoza-kutembenuza-bwino kupukuta-chrome plating-kupukuta.

Q6: Kodi kupukuta kwa pneumatic silinda pisitoni ndodo ndi chiyani

A: Panthawi yokhotakhota, dzenje lapakati lomwe limagwira ntchito yoyikapo liwonetsa kuchuluka kwa kuvala.Pofuna kutsimikizira mfundo yogwirizana ya benchmarks, dzenje lapakati liyenera kudulidwa musanagaye kuti zitsimikizire kuti ntchitoyo ndi yabwino.Pakupera, kuyesa mphesa kuyenera kuchitidwa pabwalo lakunja pafupi ndi mapeto poyamba, ndipo kugaya ndodo ya pisitoni kungathe kuchitika pokhapokha ngati vuto la kuthamanga likukwaniritsa zofunikira.Kuphatikiza pa kuwongolera kulondola kwa mawonekedwe, njira yopera bwino imafunikanso kupeza kuuma kwapamwamba pamtunda wopangidwa ndi makina kuti apititse patsogolo kulumikizana kwa ma chromium ion panthawi ya electroplating.Pofuna kuonetsetsa kuti makulidwe a chromium plating wosanjikiza wa pisitoni ndodo yomaliza ndi yofanana, kuuma kwapamtunda pambuyo pogaya bwino kuyenera kukhala pafupi ndi kuuma kwapamtunda pambuyo popaka chromium ndi kupukuta.Ngati kuuma kwapamwamba kwa ndodo ya pisitoni kumayenera kukhala kokwezeka, monga Ra <0.2 μm, kuyenera kukhala pansi.Onjezani njira yopera bwino kwambiri kapena yopukutira mutatha kupera.